As seen in the recent NCIA blog on how you can maximize your greenhouse cannabis harvests.

As the seasons change, so does the amount of light that enters into your greenhouse. Summer months may offer an abundance of natural light; however, the longer nights of winter require supplemental lighting for growers to achieve the best yield possible from their crop. Some greenhouse facilities shut down during the winter months due to natural lighting restraints, but there are easy solutions that can mean more harvests and bigger profits for growers. The first step is to target a daily light interval (DLI) number for each facility and design the supplemental light accordingly. This ensures optimal light intensity and uniformity in the facility year-round.

On Site

Recently, Colorado marijuana cultivators have begun to move into more efficient greenhouse structures. With proper planning and execution, these growers are experiencing as much or more success as indoor gardeners. It does take proper planning to get through the short days of the winter, and owners are turning towards horticulture companies to help them succeed. Based on the sun’s position in the geographical region, high tech control systems with DLI sensors can be installed to measure when the natural light falls below a certain level and the supplemental light is needed to optimize growth.

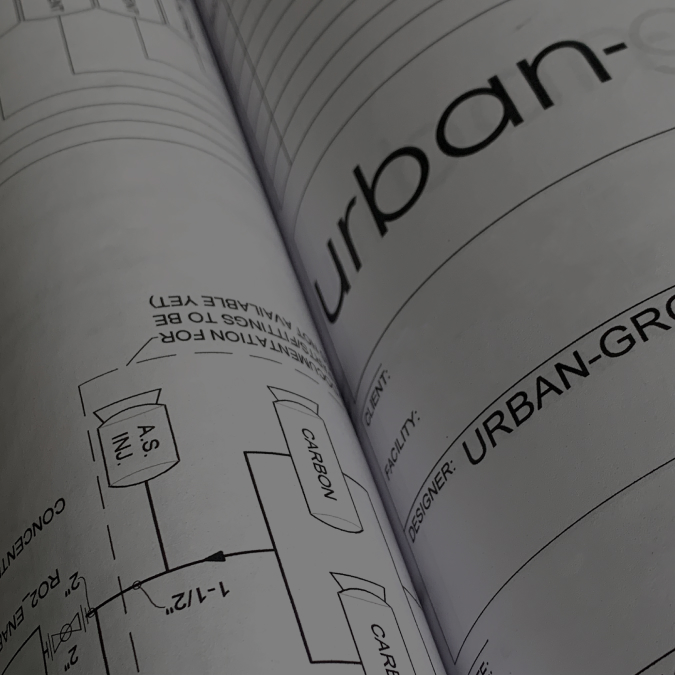

For example, at urban-gro, once we know the facility’s DLI and obstructions within the greenhouse structure, we begin the planning process and consider technical factors for the layout of the lighting system. Ensuring optimal lighting layout for the grow facility is the top priority. Incorporating lights into the structure so they create minimal shadowing is critical; this ensures that the crops are getting the optimal amount of natural light when the sun is shining.

Today, most grow facilities use 1,000-watt DE HPS light fixture, which is the most efficient light source on the market for the plant canopy. Once the lighting system is installed, it is essential that the correct intensity is aligned with the crops’ growth stage, which ranges from veg to bloom. We schedule a gradual increase of light intensity so yield is maximized and never harmed.

End Result

With supplemental lighting, cultivators can guarantee the correct amount of lighting and environmental controls for the winter months to ensure yields and profits.

Shelly Peterson serves as Vice President of Grow Light Solutions for urban-gro for the last three years. Shelly manages the company’s sales force located across the country. Her passion for eco-friendly solutions and creating a sustainable environment ensures that the commercial cultivator is provided with a lighting plan that utilizes the least amount of equipment. Further, her skills learned in the commercial lighting industry have enabled her to work with regional electrical providers to maximize available utility rebates for urban-gro’s customers. Urban-gro is a Sustaining level member of NCIA since November 2014.