Warehouses have long been a popular option for indoor agriculture. However, it is essential to note that growing cannabis or produce in a warehouse environment requires meticulous attention to detail to ensure that the conditions are optimal for plant growth. This blog post will discuss four essential tips for effective warehouse grow room design that will help you cultivate healthy, thriving crops and run a more efficient and profitable business.

Tip 1: Utilize Proper Lighting for Optimal Growth

When designing or upgrading a grow facility, the right lighting system is critical for ensuring optimal plant growth and financial performance. Light intensity directly affects plant yield and the production of secondary metabolites, making it an essential consideration when designing the facility. However, choosing the right system can be challenging with so many lighting options available.

It's critical to work with a lighting design expert to ensure that the lighting system meets the facility's specific needs and takes into consideration its interactions with other systems, such as the HVAC. A lighting system that doesn't perform as expected can result in decreased yields, reduced product quality, higher operating costs, and other unintended consequences, making it essential to work with a design team that brings extensive real-world experience to the project.

While multiple lighting solutions are available for indoor agriculture, LED lights are more energy-efficient, produce less heat, and have a longer lifespan than their less efficient counterparts. Key factors like the size of the grow room, type of crop being cultivated, and budget should all be considered when selecting the lighting system.

A well-designed and properly integrated lighting system can optimize plant growth and energy efficiency by providing the right amount of light and adjusting the light spectrum and intensity as needed. When considering the lighting system, remember that the system you choose represents a significant capital and operational expense and plays a pivotal role in determining yield, cycle time, and secondary metabolite profile, which impact revenue.

Tip 2: Design a Climate Control System for Your Plants

Maintaining the right temperature and humidity levels is crucial as they can impact plant health, growth, and even the quality of the final product.

The systems responsible for climate control include HVAC systems and dehumidifiers. These systems work together to provide heating, cooling, and dehumidification.

When designing a climate control system, consider factors such as the size of the grow room, the type of plants you are growing, and the stage of plant growth. The climate control system should maintain the plants' optimal temperature and humidity levels.

Tip 3: Understand Airflow and Ventilation Techniques for Disease Prevention

Airflow and ventilation systems help regulate the temperature and humidity in a grow room and provide a steady supply of fresh air. These systems can also help remove excess moisture, creating an ideal environment for plant growth.

Additionally, these systems can help reduce the spread of disease and pests, preventing costly crop losses.

Different types of airflow and ventilation systems are available, including exhaust fans, carbon filters, and air intake systems. When designing an airflow and ventilation system, consider factors such as the size of the grow room, the type of plants you are growing, and the stage of plant growth. The airflow and ventilation system should provide adequate air exchange to keep the plants healthy and prevent the spread of disease.

Tip 4: Use Your Space Effectively for Maximum Utilization

Maximizing available space is crucial for effective warehouse grow room design. With limited space, it's essential to make the most of it to ensure optimal conditions for plant growth.

Techniques for maximizing space utilization include vertical growing, rolling benches, and stacking systems. Vertical growing, for example, allows you to grow plants upwards instead of outwards, freeing up more floor space. Rolling benches and stacking systems allow you to maximize square footage inside the grow room. It’s important to understand that all of these options introduce key variables and may create microclimates that must be considered when engineering the building’s mechanical systems.

Consider the following best practices:

- Work with an architect and engineer with industry experience

- Design a layout based on understanding utility specifications

- Implement purposeful space allocation

- Prioritize security and access

- Consider light, water, and nutrient management

- Ensure the room provides adequate airflow and ventilation

By following the best practices listed above, you can design a grow room that effectively maximizes the use of available space.

Creating Optimal Conditions for Plant Growth

Proper warehouse grow room design is essential for growing healthy, thriving plants. By utilizing proper lighting, designing a climate control system, understanding airflow and ventilation techniques, and using your space effectively, you can ensure optimal conditions for plant growth.

It's crucial to consider the specific needs of your plants and make adjustments to your grow room design as needed. By following these four tips, you'll be well on your way to growing healthy, thriving plants in a warehouse environment.

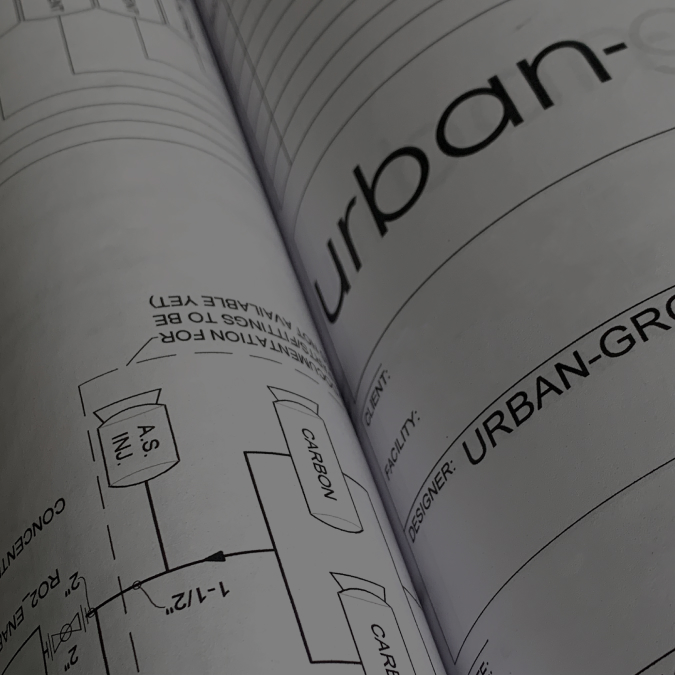

We encourage you to consider these tips when designing your warehouse grow room and to learn more about urban-gro’s approach to indoor agriculture. With our experience in over 1,000 Controlled Environment Agriculture facilities and combined hundreds of years of cannabis and produce expertise, you can ensure optimal conditions for plant growth and success in your indoor agriculture operation.